What are Aluminium Panel Doors?

Most Door Suppliers in the UK are selling Aluminium Panel Doors. These are not the best aluminium doors available in the market, but still better than timber and uPVC doors due to their durability, low maintenance, and modern look.

An Aluminium Panel Door is very similar to a double-glazed door in looks. It consists of an aluminium frame with an aluminium door leaf. Similar to any window or glazed door the aluminium panel door leaf consists of a sash usually 50-60mm thick with a 28mm thick aluminium insulated door panel instead of a 28mm double-glazed panel, creating a rebated look.

The aluminium panel front door has a double frame look with a frame and sash. The aluminium panel door with a sidelight will have an additional frame of the sidelight, giving it a three-frame look. The insulated aluminium door panel is made of two aluminium sheets glued to an insulation board on each side. The aluminium insulated panels are powder coated in a RAL colour of choice. The panel can have numerous designs with infill glazed units, stainless steel trims and grooves on the panel.

These doors are manufactured in-house by door suppliers in the UK by using local aluminium profiles (frames) and outsourcing the aluminium insulated door panels. To cut corners and increase profit margins many door suppliers use cheap quality aluminium insulated door panels. In this article, we will be comparing and contrasting cheap and high-quality aluminium panel doors to inform your decision to buy an Aluminium Panel Door.

-

Cheap Aluminium Panel Doors

The basic components of an aluminium panel door are the door frame, the sash and the infill aluminium insulated door panel. The cheaper Aluminium Panel Door uses inferior quality door profiles (frames) and aluminium door panels with thinner aluminium sheets.

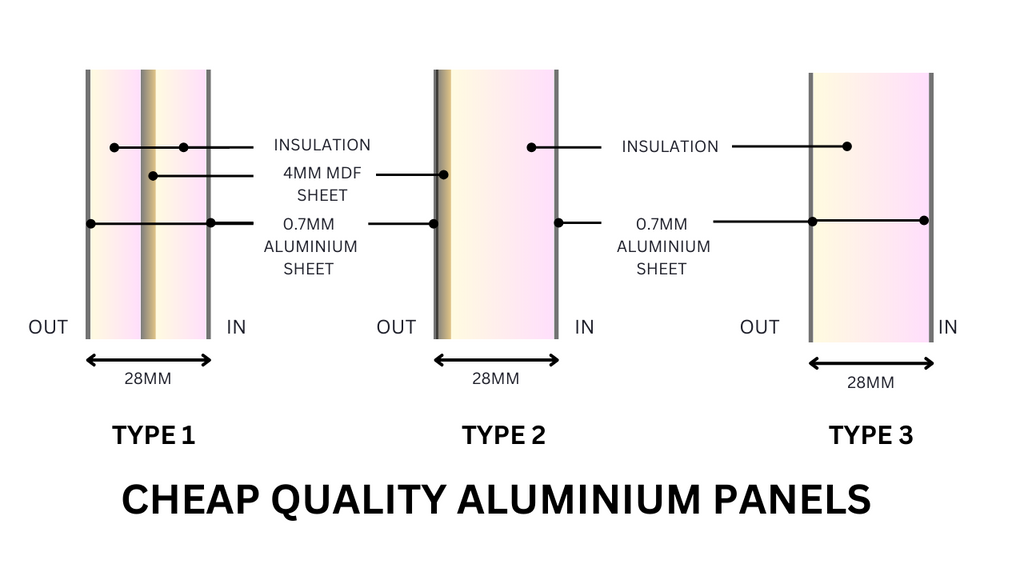

The image below explains three types of cheap quality aluminium door panels in popular in the market.

TYPE 1

This aluminium insulated door panel construction consists of a 28mm panel with a 4mm MDF board used as a core sandwiched in between the rigid insulation, with a 0.7mm aluminium sheet. As a thin aluminium sheet is used, hence to strengthen the panel a 4mm MDF board is used. However, this still doesn't prevent the door from denting easily. Moreover, the use of timber ( MDF) can further cause the door to warp or bow due to temperature fluctuations and exposure to sunlight.

TYPE 2

Type 2 of the aluminium door panel has the 4mm MDF board behind the aluminium sheet on the exterior face of the door to mitigate the problem of denting due to the thin aluminium sheet being used to cut on the price. However, as the inner face does not have the MDF backing it is prone to denting and is not impact resistant. The issue of warping and bowing due to the use of timber also persists in this type of aluminium insulated door panel.

TYPE 3

This is the worst type of aluminium door panel as the use of thin aluminium sheet on either side of the insulated core, gives no protection against impact and is prone to denting. However, chances of warping are reduced as no timber is used.

Please find below the characteristics, advantages and disadvantages of these doors:

Characteristics:

- Thinner Aluminium Sheets -These cheap panel doors come with thinner aluminium sheets as low as 0.7mm thick, making them prone to denting easily due to impact.

- Cheap construction- The local shop fitters and door fabricators buy these cheap aluminium sheets of 0.7mm thickness and glue these manually to the rigid insulation by using clamps instead of using a pressing machine. Quality Aluminium Door Panels are factory-made using a pressing machine. This glues to aluminium sheet evenly to the insulation core. As the cheaply constructed aluminium door panels are glued in-house manually, using clamps, these are not evenly glued and hence result in poor construction that deteriorates quickly.

- Steel Sheet used instead of Aluminium- Several shop fitters use steel sheets instead of aluminium to produce the door panels as use it with aluminium frames to mislead the customers, marketing these as aluminium panel doors. As these are made cheapily in-house by powder coating the sheets without chemically cleaning them, these are prone to rusting. Customers should vet the fabricators and ask them to provide a written confirmation that the panels are made of aluminium sheets and not steel when buying an aluminium panel door.

- Fewer design options - The use of thinner aluminium sheets limits the designs that can be created for aluminium door panels. Contemporary Designs using grooves in the aluminium door panels is not possible in the cheap panels as the minimum depth of the groove is 0.5mm, which is not possible in a 0.7mm sheet. Minimum aluminium sheet thickness for designs with grooves is 1.5mm. Hence only designs with glass and stainless steel trims are available in the door panels made of thin aluminium sheets.

-

Door Handle - With the bar stainless steel handles gaining popularity, most aluminium door manufacturers tend to use these on the doors. However, due to lower sheet thickness on cheap aluminium panel doors, the bar handle cannot be installed on the panel as it will bend easily. Therefore, in these doors, the only option is to use a 45-degree bar handle on the sash (frame) of the door. This is not as aesthetically pleasing as the 90-degree bar handle. Moreover, these cheap aluminium panel doors are generally made in-house by local fabricators by sourcing the panel from one supplier and the profile from the others. So, these bar handles don't come integrated into the door and have to be installed at a later date by drilling in the sash. Now to hide the screws visible on the rear face of the door, they install another bar handle using headless screws. However, this is only a pull handle and unlike a lever handle will not engage the door lock and hence cannot assist in opening or closing of the door. To mitigate this problem, they then install a thumb turn to operate the door. However, it is not as easy as a lever handle in operation as one has to use two hands, one to open the door with the thumb-turn and the other to pull the door. Arguably, one can pull the door with the knob on the thumb turn handle, however, it is a small knob and not very convenient to operate the door daily.

- Lower initial cost - Due to the use of thinner aluminium sheets the cost of the aluminium doors made using these aluminium panels will be cheaper than the ones made using quality products. But as you get what you pay for these will either not look that great compared to quality aluminium panel doors or will not last as long as them.

Advantages:

- Budget-friendly option - If one wants an aluminium front door but is tight on budget, then this could be the option.

Disadvantages:

- Prone to dents and scratches - The use of thinner aluminium sheets makes these doors easy prey to denting and scratching.

- Less aesthetically pleasing - As these are cheaply constructed so will lack aesthetic appeal. Moreover, these are available in limited designs without grooves.

- Powder Coating Issues - As the local shop fitter and fabricators buy these cheap aluminium sheets from local suppliers and powder-coat these in-house without chemically cleaning and treating the aluminium sheets before powder coating, these do not get an even colour coating and are prone to the paint bubbling and chipping off at a later date.

- Shorter lifespan - The use of cheap materials, thinner aluminium sheets and poor workmanship will lead to a shorter lifespan for these aluminium panel doors.

2. Good Quality Aluminium Panel Doors with Thicker Aluminium Sheet

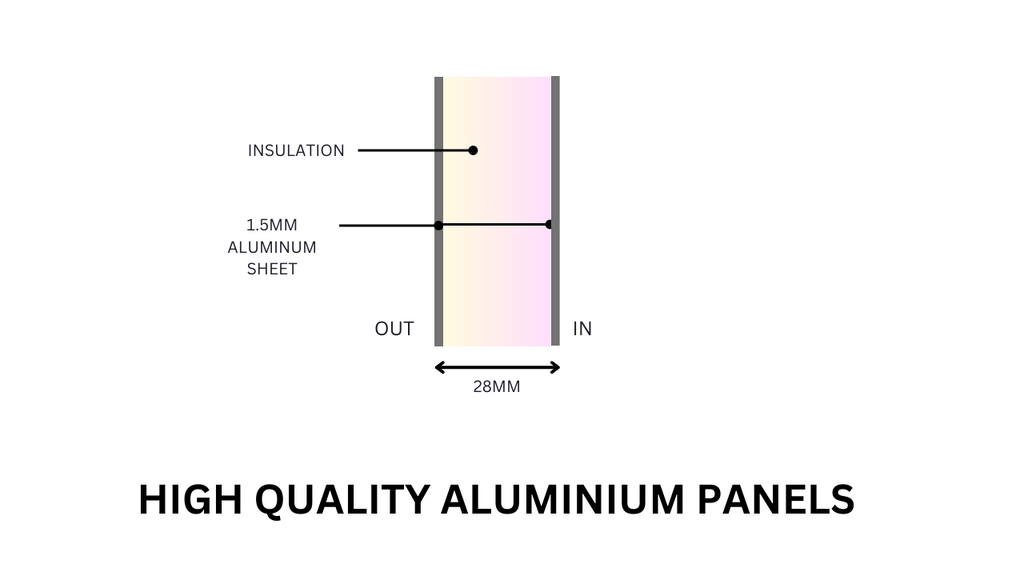

Good Quality Aluminium Panel Front Doors use thicker aluminium sheets glued to the insulation core on either side. The maximum thickness of the aluminium sheet used is 1.5mm. These are usually sold as 28mm thick panels, but thicker panels of 36mm and 44mm are also available. 28mm thick aluminium panels are commonly used in Aluminium Panel Front Doors as the double glazing panels used in most aluminium door constructions ( bi-fold doors, aluminium windows) are also 28mm thick. Moreover, the glazing bead used on these doors is equipped for a 28mm thickness, hence this is the most commonly used aluminium door panel thickness.

Quality Aluminium door panels are factory-made using a pressing machine to evenly glue the aluminium sheets to the glazing ( if any in design ) and the insulated core. These are manufactured using aluminium sheets that are first chemically cleaned and treated before powder coating these to ensure that the paint is evenly spread, and properly adhered to the sheets to avoid issues like blistering and the paint chipping off with use.

Characteristics:

- Thicker aluminium sheet - A thicker aluminium sheet of 1.5mm thickness provides increased strength and rigidity to the aluminium door panels less prone to scratches and dents.

- High-Quality Materials and Finish - Factory-produced panels using more robust construction with thicker aluminium sheets powder coated to a good standard leads to a durable high-quality product with an immaculate finish.

- Wider range of design options - As thicker sheets of aluminium are used these aluminium door panels can have a variety of designs including grooves, stainless steel trims and glazed panels.

-

Door Handles - Unlike the cheap aluminium panel doors, these have an integrated 90 degrees Stainless Steel Bar Handle on the panel on the front face and a lever handle on the rear face of the door. This makes the door visually more appealing and ergonomic in design, as it is much easier to operate the door with a lever handle with just a single hand.

Advantages:

- Enhanced durability - Due to the use of thicker aluminium sheets, 1.5mm in thickness, these aluminium insulated door panels provide better dent and impact resistance, making them durable in the long run.

- Visually more attractive - The quality and finesse of these quality aluminium door panels is far superior to their cheap counterparts making them aesthetically more pleasing.

- Numerous design options - The use of thicker aluminium sheets allows for designs with grooves, unlike the cheap aluminium door panels. So one is spoilt for choice between designs with grooves, glass and stainless steel.

- Longer lifespan - Good workmanship, robust construction and use of quality materials and powder coating gives a longer life span to these high-quality, factory-made aluminium insulated door panels.

Disadvantages:

- Higher cost compared to cheap options - The only disadvantage of the high- quality aluminium door panels is their higher cost compared to their cheap counterparts, but as they say, you get what you pay for, these doors last much longer than the cheap options available in the market, making them cheaper in the long run.

TABLE COMPARING CHEAP AND HIGH-QUALITY PANEL DOOR

FEATURES |

CHEAP ALUMINIUM PANEL DOORS |

HIGH-QUALITY ALUMINIUM PANEL DOORS |

Thickness of the aluminium sheet used |

0.7mm - 1mm |

1.5mm |

Core Construction |

Insulation with MDF reinforcement | Insulation |

Thermal Value |

Lower than High-Quality Panel Doors | Better than Cheap Aluminium Panel Doors |

Workmanship/Finish/Quality |

Inferior than High-Quality Aluminium Panel Doors | Superior than Cheap Aluminium Panel Doors |

Designs |

Limited Designs only- Designs with Grooves not possible | Any Design with Stainless Steel, Glass and Grooves possible |

Powder Coating |

Cheap quality powder coated paint prone to blistering and chipping off | Quality Powder Coated paint that lasts ages |

Longevity |

Short-lived | Long Lasting |

Price |

Cheaper than High-Quality Panel Doors | Slightly Expensive than Cheap Aluminium Panel Door |

Conclusion

- The key differences between cheap and high-quality aluminium panel doors is as follows:

- Thickness of the aluminium sheet used – Cheaper quality aluminium panels will be constructed with 0.7mm Aluminium Sheets. In comparison, the high-quality counterparts will have aluminium sheets up to 1.5mm thick, making them more durable and impact-resistant.

- The core construction – As the cheap Aluminium Door Panels are made of thinner aluminium sheets, these use a 4mm MDF sheet to reinforce it along with the insulation. While the high-quality aluminium panels have only an insulation core. The use of timber (MDF) can cause warping and bowing in the door due to temperature fluctuations and exposure to the sun.

- Workmanship – The high-quality aluminium insulated door panels are factory-made, using pressing machines and quality control systems concerning powder coating, hence they reflect good workmanship. Whereas, the cheap counterparts are made by local fabricators, sourcing cheap materials, and manually glueing the aluminium sheets to the insulation and MDF sheet using clamps. This may result in uneven pasting of the aluminium sheets resulting in debonding of the materials at a later date.

- Powder-coated paint – The cheap aluminium door panels may be powder-coated in-house in the local fabricators’ small factory. With limited resources available, the fabricator may or may not chemically treat or clean the sheets before powder coating them. This will result in the paint not adhering evenly to the surface of the aluminium sheet resulting in blistering and paint chipping off at a later date. However, in the high-quality aluminium door panels, this issue is mitigated as the aluminium sheets are powder-coated in huge plants to a professional standard undergoing quality checks to produce even paint that is less prone to scratches and lasts for ages to come.

- Designs with Grooves – Designs with grooves are only possible in high-quality aluminium door panels as the grooves require a minimum 0.5mm depth, this is only possible in a thicker aluminium sheet of 1.5mm.

- Price – The cheap quality aluminium door panels are cheaper than their counterparts the high-quality aluminium door panels due to poor workmanship, lower quality and limited designs.

- Longevity – The use of high-quality material and excellent workmanship make the high-quality aluminium door panels last longer than their cheaper counterparts.

Based on your design and budget you can choose the best aluminium panel front door to suit your needs. Glasswin Front Doors produces high-quality panel doors using quality aluminium insulated panels, as our Standard Series Doors. These panels are made using top quality aluminium sheets 1.5mm thick with an insulated core in more than 65 designs including grooves, glass and stainless steel.

We also supply aluminium door panels to local door manufacturers in the UK. For retail and trade inquiries, please call us at 0330 122 4562 or email us at sales@glasswin.co.uk